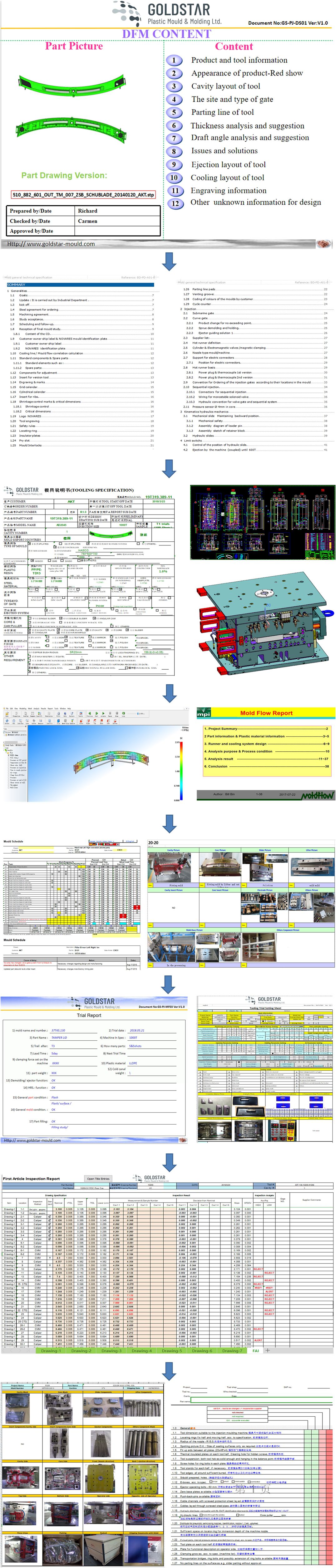

| 1.Part Analysis | We provide part feasibility report (DFM ) after receiving final 3D part data |

| 2.Customer Tooling Standard | Have a meeting to study and learning customer tooling standard with all the related staffs |

| 3.Mould Specificationg Sheet | Detailed mould specification sheet as per the customer's mould requirements which includes the mould steel, injection machine information etc will be provided to customer. |

| 4.Mould Drawings Design | After we receive confirmation of the mould specification sheet, we will provide 3D and GA within 3-5 working days. 2D will be convert from 3D if customer requested it. |

| 5.Mould Flow Analysis Report | We will provide mold flow analysis report when we receive confirmation of mould feedback. |

| 6.Mould Manufacturing Schedule | Once get the approval of mould design,we will start to order steel and machining,during this period,we will provide weekly report with some updated process photos from the mold base,core & cavity,electrodes,components,CNC machining, EDM, wire cutting, polishing,fitting every Monday to show what we have done last week till finish the mold. |

| 7.First Article Inspection Report | Mould sampling video, part picture, FAI report, injection parameter list, parts shipment waybill will be sent to customer as a com plete mould trial report from each mould sampling. Also issues report with problem, action and lead time will be provided to customer. |

| 8.Mould Shipment | Our QC team check mould according to mould checking list. Meanwhile, final mould drawing, mould checking list, steel certifications, injection parameter, electrodes will be shipped together with moulds. Also related files will be sent to customer by email or FTP as backup. |

After the approval is passed, we will contact you within 24 hours.